Top Beryllium Copper Rod Suppliers and Essential Spot Welding Electrodes for Resistance Welding

Top Beryllium Copper Rod Suppliers and Their Products

When it comes to resistance welding, the choice of materials such as beryllium copper rods and spot welding electrodes plays a crucial role in ensuring strength, durability, and conductivity. The right components can make all the difference in your welding performance. In this blog, we’ll take a closer look at some of the key materials and their applications.

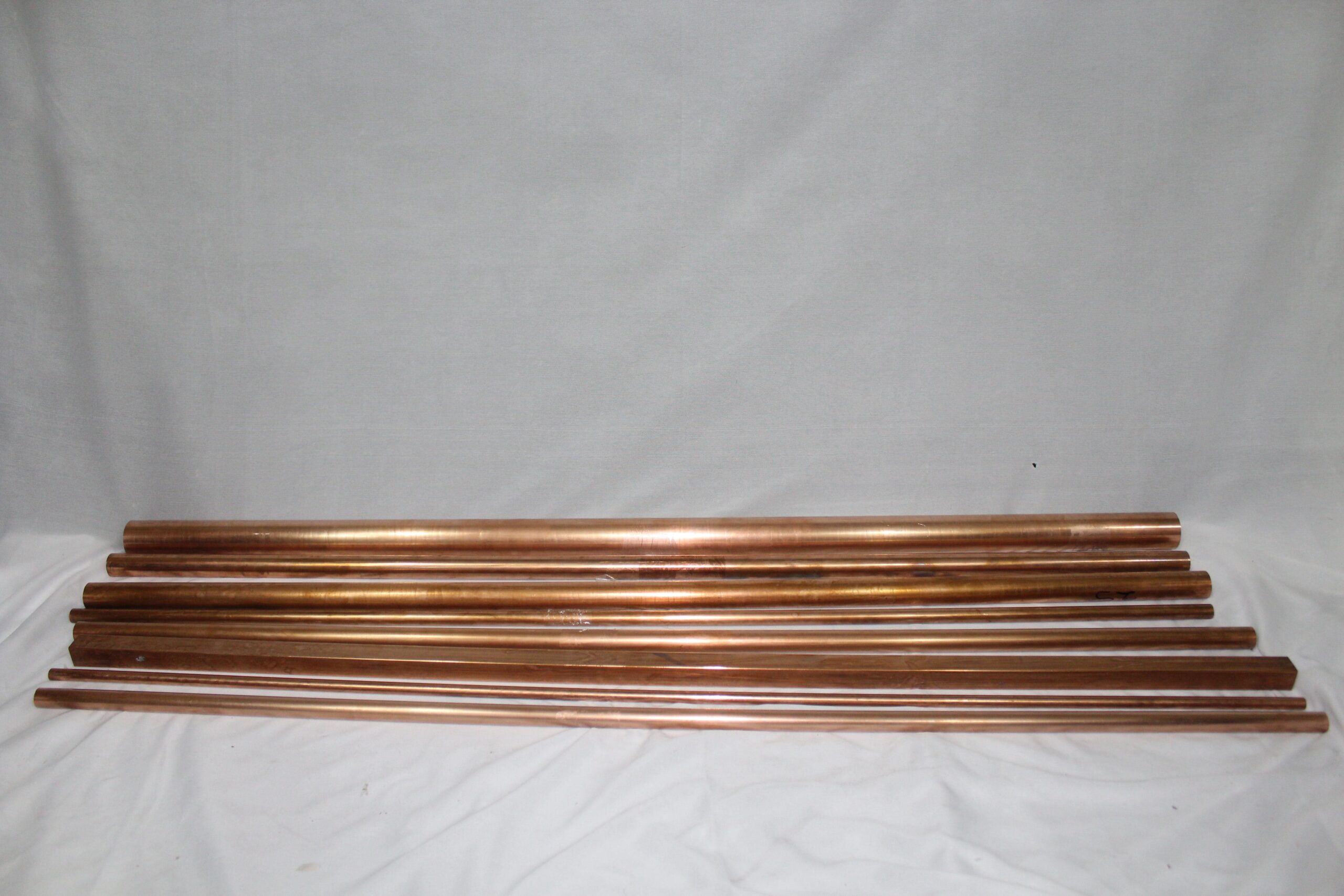

1. Beryllium Copper Rod Suppliers

Beryllium copper rod suppliers provide high-quality materials for various industrial applications, including welding. Known for its strength, conductivity, and non-sparking properties, beryllium copper is a top choice for manufacturers. Whether you need a beryllium copper round bar or a C17300 beryllium copper rod, suppliers today offer a range of options to meet your specific requirements.

2. Spot Welding Electrodes

Spot welding is a widely used method in automotive, electronics, and metal fabrication industries. One of the most critical components in this process is the spot welding electrode material. Choosing the right electrode can ensure consistent weld quality and extend the lifespan of your welding machine.

For instance, copper electrodes for spot welding are popular due to their excellent electrical conductivity and resistance to wear. Additionally, tungsten spot welding electrodes are commonly used in applications requiring higher heat resistance. Depending on the type of welding, different electrodes used in spot welding are available, including resistance spot welding electrodes that enhance welding efficiency.

3. Electrodes for Resistance Welding

In resistance welding, selecting the right electrode is essential for optimal performance. Common choices include resistance welding copper and tungsten copper bars, both known for their durability and heat tolerance. Whether you are working with seam welding electrode material or spot welding copper rods, the right electrode ensures that the welds are strong and reliable.

Specialized suppliers offer a variety of electrodes for resistance welding tailored for specific applications. For example, electric resistance spot welding uses electrodes made from copper alloys, while electric resistance seam welding uses electrodes that can handle continuous welding tasks.

4. Spot Welding Machines and Electrode Material

To achieve high-quality spot welds, pairing the right machine with the correct spot welding machine electrode is crucial. The 1cmw spot welding machine, for example, is widely known for its efficiency in producing clean welds, especially when used with the appropriate resistance welding electrode material.

Whether you're looking for tungsten copper bars or copper electrodes for spot welding, ensuring you have the right combination of machine and materials can significantly enhance your welding results.

For more information or to get a quote, Contact Us today!