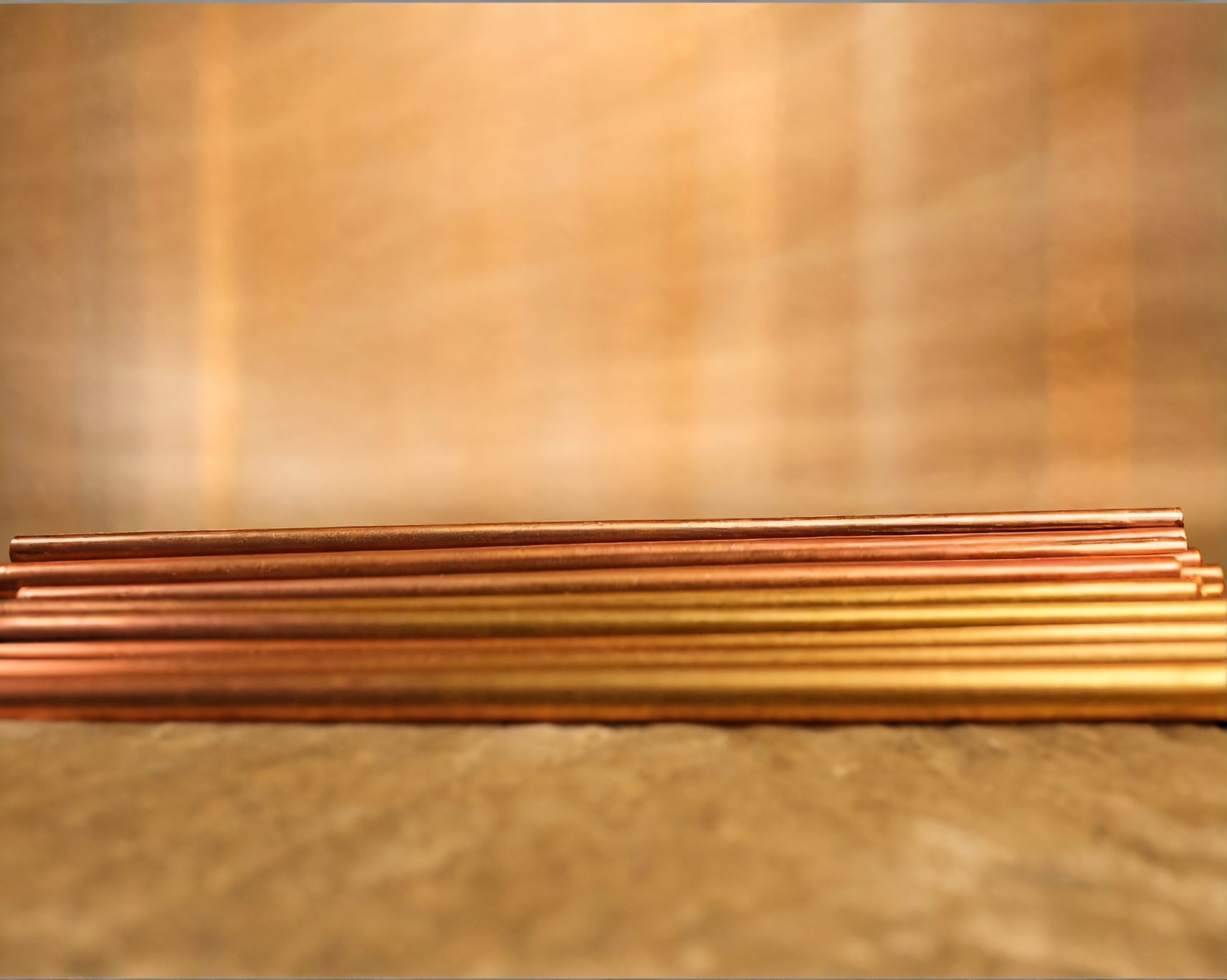

C18150 Chromium Copper Rods: Resistance Welding Solutions

Enhance your welding performance with premium C18150 rods and wheels.

When it comes to premium materials for resistance welding, C18150 chromium copper rods are among the most reliable choices for industries that require durability and precision. As trusted beryllium copper rod suppliers, we specialize in providing C18150 rods and wheels designed for various applications, including spot welding, seam welding, and resistance welding. Known for their superior strength and conductivity, these rods are the perfect fit for manufacturers looking to enhance performance and longevity in welding processes.

Spot Welding and Resistance Welding: The Role of C18150 Chromium Copper

The choice of materials in welding electrodes is critical, and C18150 chromium copper is a top-tier option due to its excellent electrical conductivity and high wear resistance. Whether you're using a spot welding machine electrode or working with a seam welder, C18150 chromium copper rods provide the durability needed for high-stress applications. For industries requiring precision in 1cmw spot welding or electric resistance spot welding, our C18150 rods are ideal for reducing wear and tear while ensuring efficient energy transfer.

Advantages of C18150 Chromium Copper in Welding Electrodes

For spot welding, the electrode material plays a significant role in the quality and consistency of the weld. Our C18150 rods outperform other materials, like tungsten copper, in key areas such as heat dissipation and resistance to deformation. These features make them highly effective in resistance spot welding electrodes and seam welding electrode materials. Using chromium copper electrodes in your resistance welding copper applications not only extends the life of the electrode but also enhances the overall welding quality.

Electrodes for Resistance Welding: Why Choose C18150?

In both electric resistance seam welding and spot welding, the right resistance welding electrodes can significantly improve production efficiency. Electrodes used in resistance welding, particularly those made from C18150 chromium copper, offer excellent performance under high current and pressure. This makes them the go-to choice for high-duty cycles in industries that rely on seam welders and resistance spot welders. With superior conductivity and strength, our C18150 rods ensure longer-lasting performance compared to other materials.

Spot Welding Machine Electrode Material: The C18150 Advantage

Whether you're in need of a spot welding copper rod or a resistance welding electrode material that can withstand high thermal and mechanical stress, C18150 chromium copper rods are the optimal choice. These rods offer a perfect balance between conductivity and strength, ensuring that your spot welding electrodes last longer and require less frequent replacement. This makes C18150 chromium copper a cost-effective solution for businesses looking to improve their welding processes.

Invest in Quality with C18150 Chromium Copper Rods and Wheels

For businesses seeking the highest quality in resistance welding and spot welding electrode materials, our C18150 chromium copper rods and wheels provide unmatched performance. Whether you need durable electrodes for your spot welding or seam welding operations, choosing C18150 chromium copper ensures you get the best results with less wear, reducing downtime and increasing productivity. If you're looking for a seam welder for sale or need customized C18150 rods for your welding machines, we're here to supply you with the best materials for your specific needs.